Cleanroom Facility Basel

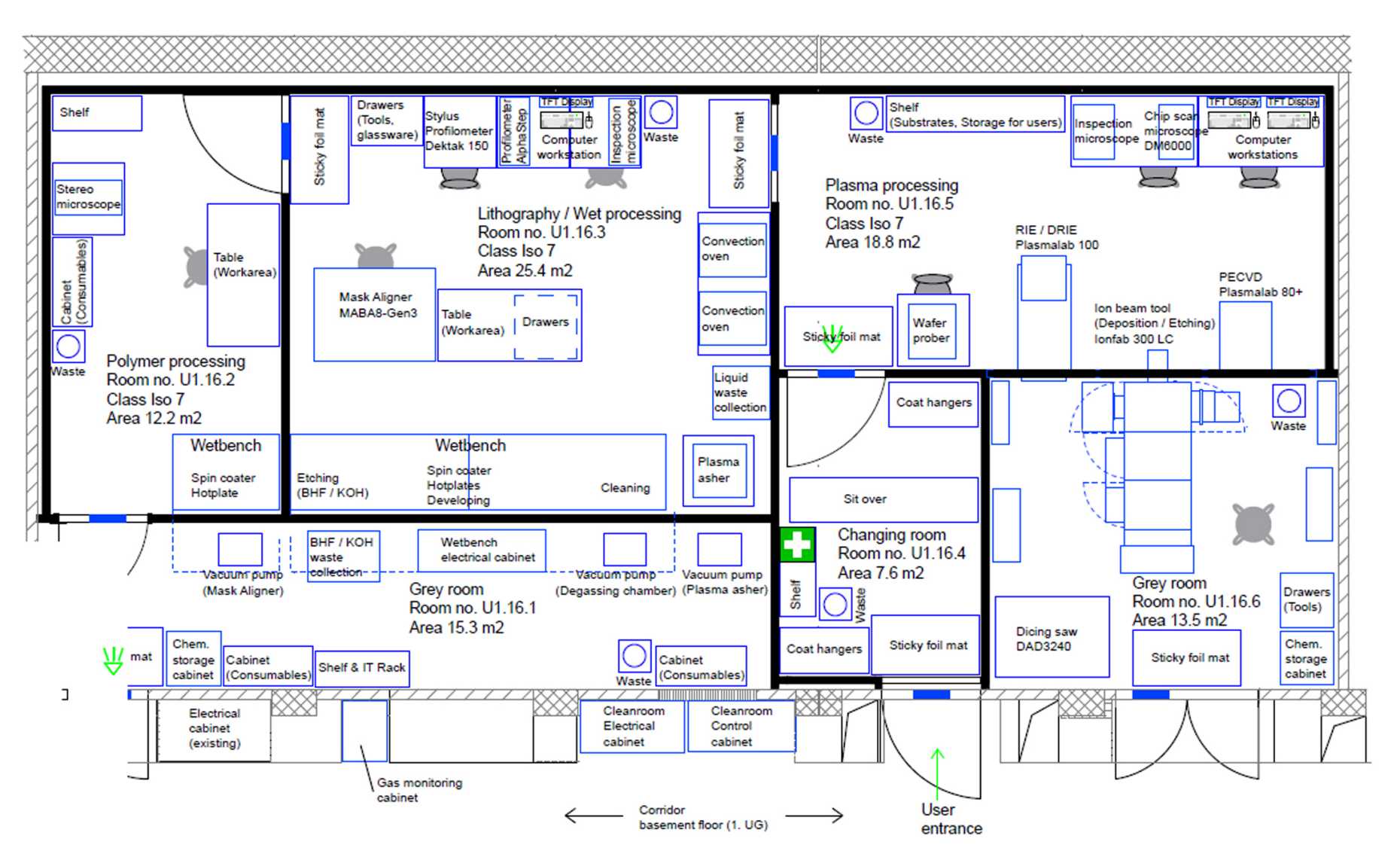

Welcome to the D-BSSE Cleanroom Facility. With state-of-the-art tools and comprehensive processing knowledge, we offer the scientists means to fabricate complex microsystems, microelectromechanical systems (MEMS), and microfluidic systems.

Our mission:

- Provision of tools and processes to fabricate complex micro- and nanostructures

- Support of users with project-specific consulting and process development

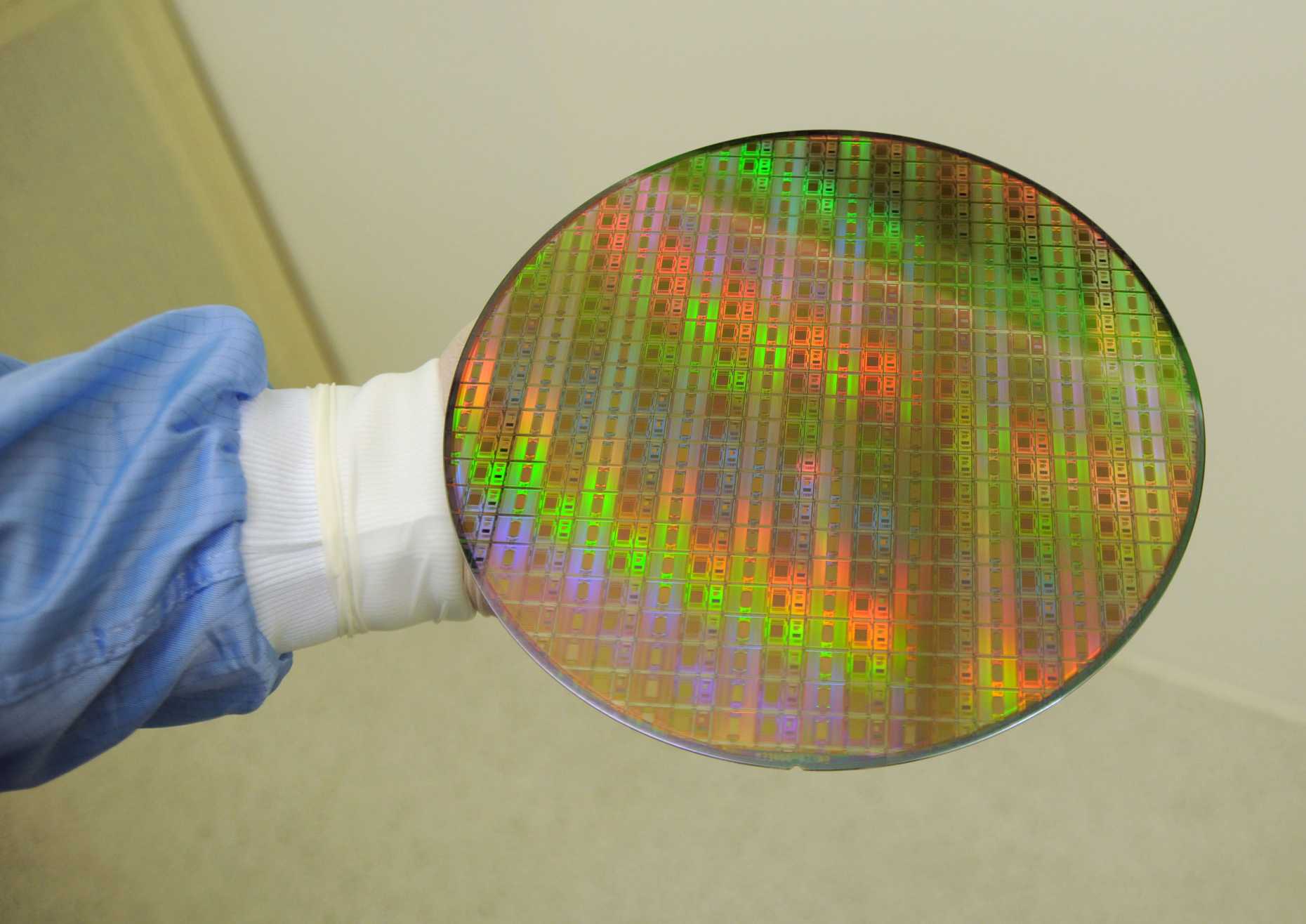

As one of the first research cleanroom facilities in Switzerland, we have the capabilities to process substrate sizes up to 8 inches (200 mm) diameter.

Equipment

The cleanroom facility is equipped with state-of-the-art tools to perform thin-film deposition, etching processes and lithography (proximity and contact printing) with good reproducibility to fabricate complex microsystems.

Dry processing

Oxford Instruments Plasmalab 80+:

- Plasma Enhanced Chemical Vapor Deposition (PECVD)

- Deposition of SiO2, Si3N4, SiOxNy films

Oxford Instruments Plasmalab 100:

- Reactive Ion Etching (RIE) and Deep Reactive Ion Etching (DRIE)

- Etching of Si, SiO2, Si3N4, SiOxNy and organic materials

- Fabrication of high-aspect-ratio structures in silicon.

- Inductively-Coupled Plasma (ICP) option for up to 4 inch wafers

Oxford Instruments Ionfab 300LC:

- Ion Beam Deposition (IBD) and Ion Beam Etching (IBE)

- Deposition of metallic and nonmetallic materials

- Etching of metallic and nonmetallic films and substrates.

- Very good uniformity (etching and deposition)

Microwave plasma asher:

- Removal of photoresist masks and surface activation

Wet processing

Goller Reinraumtechnik wet benches:

- KOH bath (temperature controlled) for anisotropic silicon etching

- BHF bath (room temperature) for SiO2 etching

- Quick-dump-rinse bath for de-ionized water rinsing

Lithography

Karl Suss MABA8-Gen3 mask aligner:

- 1:1 pattern transfer from glass or foil masks (contact and proximity printing)

- Broadband illumination (350 – 450 nm wavelength)

- Alignment accuracy of 0.25 µm; optical resolution down to 0.5 µm

Goller Reinraumtechnik lithography wet benches:

- Substrate cleaning (Ultrasonic de-ionized water bath, Spin rinse dryer, QDR bath)

- Hotplates for dehydration, priming, soft and hard baking

- Spinner for developing and resist stripping

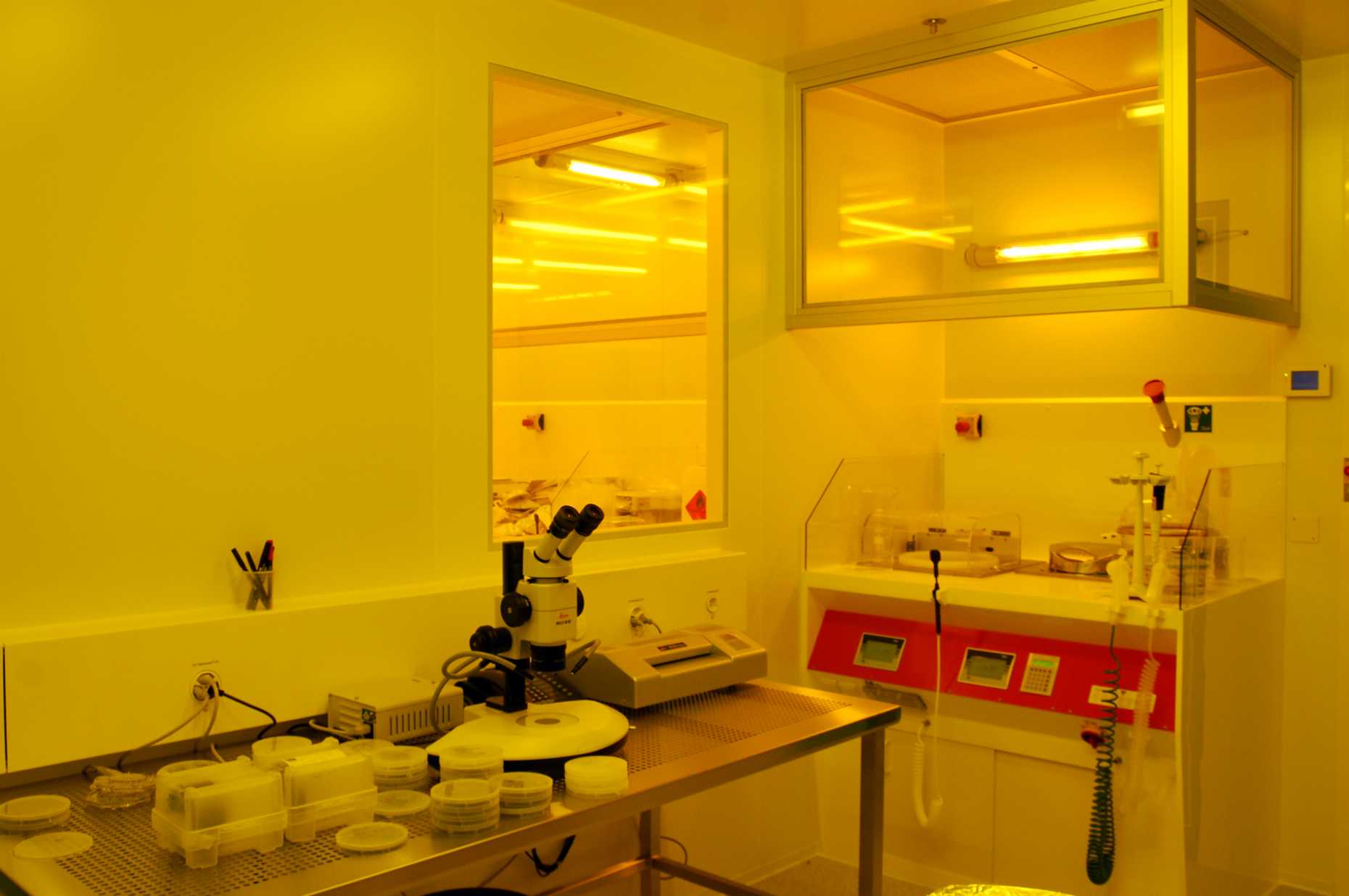

Polymer processing

- Separated area for polymer processing to avoid contamination of other processes.

- Spin coater, hotplates, degassing chamber: SU-8 and PDMS layer formation, casting and molding, packaging

Inspection and analysis

Optical microscopes:

- Nikon and Zeiss inspection microscopes

- Leica DM6000 chip scanning microscope

Surface and film analysis

- Veeco Dektak 150 stylus profilometer: film thickness and stress measurements

- KLA Tencor AlphaStep 200: film thickness measurements

- Four-point probe: resistivity measurement of metal films and semiconductors.

- Zeiss Axiotron: optical film thickness measurements

- Wafer prober: electrical tests on wafer level

Packaging

- ESEC 3088i Wire bonder: manual and automatic wire bonding

- Kulicke & Soffa 4526 manual wire bonder

- Flip-chip bonder

- Ultron Dicing-tape laminator

- Disco DAD3240 dicing saw

- Disco DCS1440 cleaning system

Meet the Team

Mattenstrasse 26 Mattenstrasse 26

4058 Basel 4058 Basel

Switzerland Switzerland

+41 61 387 34 17 +41 61 387 32 12