Microbiology & Molecular Biology Automation

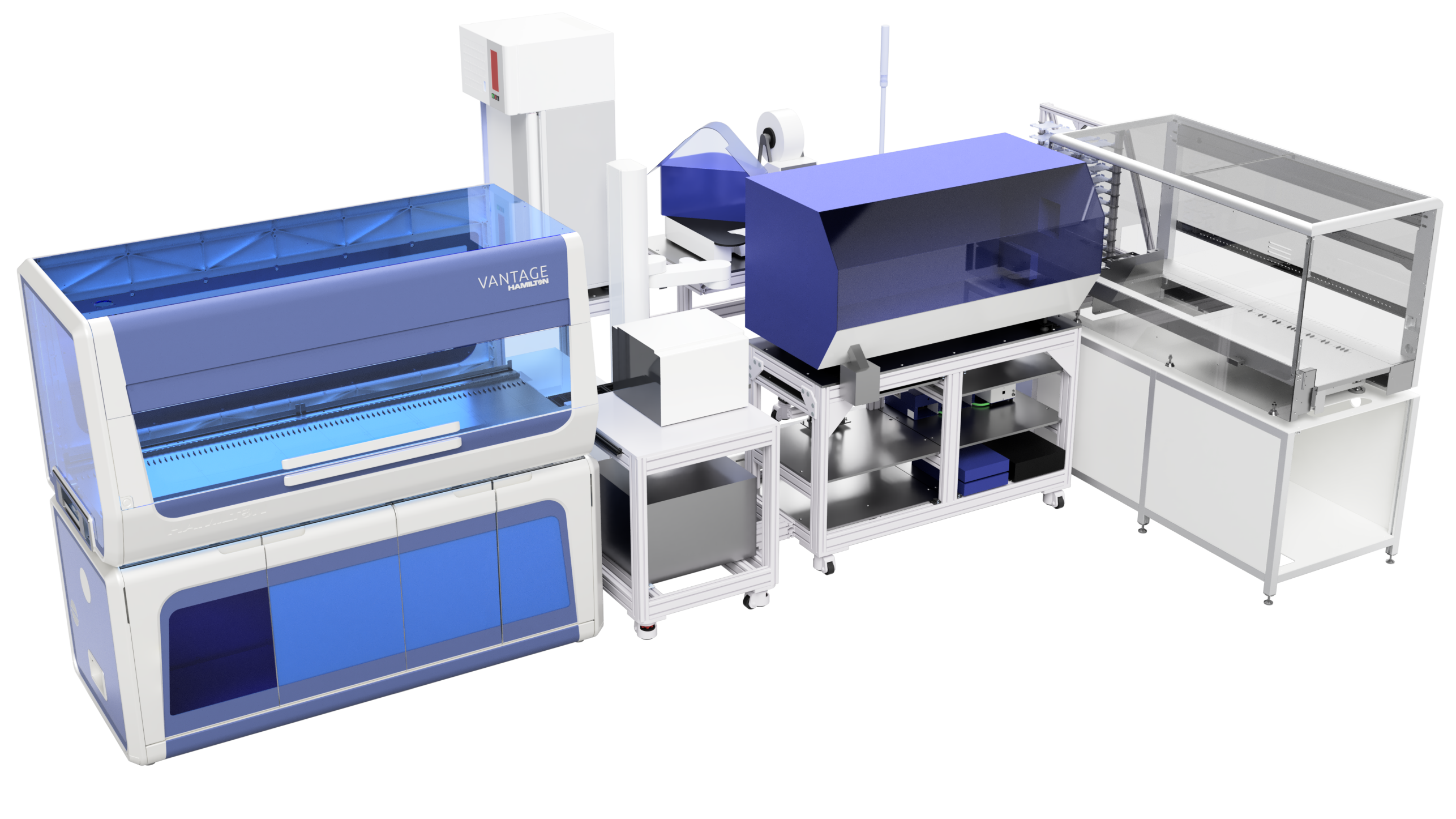

Our microbiology and molecular biology automation lab specializes in molecular biology assays and microbial cultivation, including E. coli and yeast cultures. Utilizing state-of-the-art robotic systems, we automate essential processes such as colony picking, thermocycling, continuous growth and reporter protein expression monitoring, and precise manipulation of assay compounds. This advanced automation streamlines workflows, ensures consistent and reproducible results, higher throughputs and reduces the risk of human error and contamination.

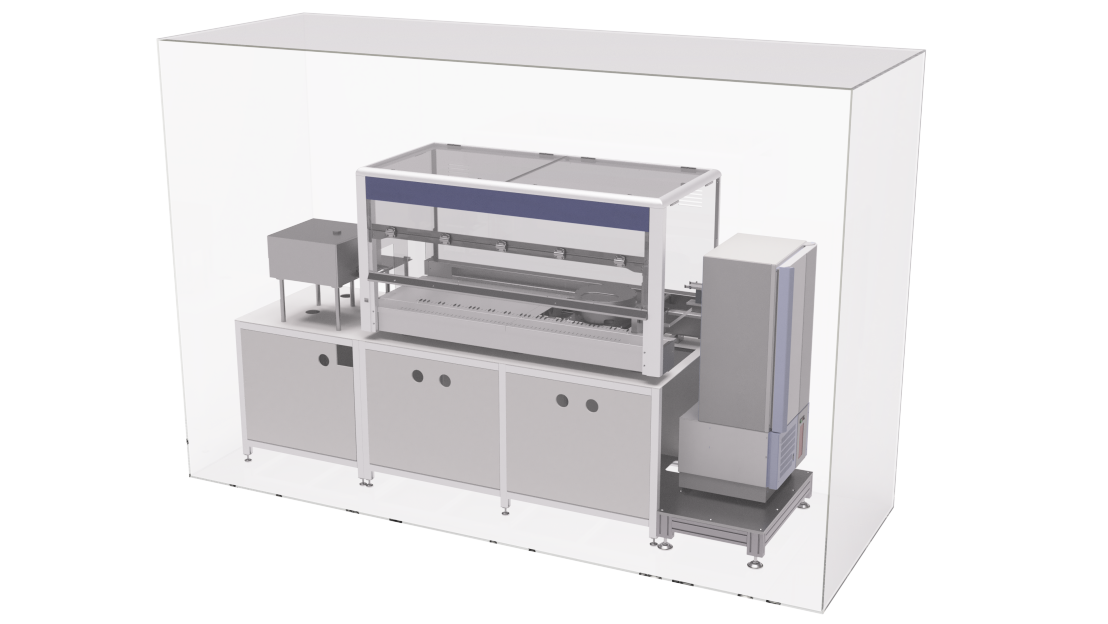

In addition to our large Microbiology and Molecular Biology system, we have also a small, dedicated BSL-2 system that is placed in an enclosure enabling it to handle BSL-2 samples and workflows. It consists of a central liquid handling robot, a plate reader, a plate sealer, a centrifuge, and a humidity and temperature controlled (heat or cool) incubator. This setup allows you to perform a large variety of workflows with your BSL-2 samples.

In modern biological research, coordinating multiple automated devices is essential for efficient and accurate experimental workflows. Scheduling software, such as HighRes Biosolutions' CellarioScheduler, which we use in this lab, facilitates this integration by enabling scientists to design, execute, and monitor complex protocols across various laboratory instruments. These platforms allow for the seamless orchestration of tasks among devices like liquid handlers, plate readers, and incubators, ensuring synchronized operations and optimal resource utilization. This capability allows multiple users to run their workflows in parallel, interleaving tasks as needed. By employing such scheduling solutions, you can enhance throughput, maintain consistency, and reduce manual intervention, ultimately accelerating your research.

Our liquid handling robots (link liquid handlers) can prepare virtually any reaction that can also prepared manually in 96-well PCR plates, seal the PCR plates (link sealer), and run up to 2 thermocyclers (link thermocyclers) simultaneously. More plates can be processed in succession automatically.

Can handle protocols with <= 20 thermocycled plates and <= 7,680 samples simultaneously (with 384-well plates) using our Custom Automation Solutions.

For more information, please visit our wiki.

As our system is equipped with liquid handlers and thermocyclers, you can simply bring your plasmid/assembly/library plate and a plate of competent cells which are then combined and heat-shocked for a transformation. Additionally, the preparation of fresh competent cells is possible with a workflow that involves liquid handlers and our automated centrifuge.

For more information, please visit our wiki.

Our liquid handlers and colony picking robot can plate cultures in various layouts and formats onto agar plates. Additionally, gradient plating is possible to make sure that individual colonies can be subsequently isolated.

For more information, please visit our wiki.

Our colony picking robot can recognize colonies and select them based on size, shape, or fluorescence. The colonies that fulfill the selection criteria can then be picked into target plates with speeds of <= 3,000 colonies per hour.

For more information, please visit our wiki.

Our colony picking robot can also pick into PCR plates or th eliquid handling robots can take samples of previously picked colonies and prepare the reactions for a colony PCR. These reactions can then run on our automated thermocyclers.

For more information, please visit our wiki.

If you have a list of wells that you want to transfer, e.g. wells containing colony PCR-positive clones or library members crossing a certain fluorescence threshold, you can transfer those into a new plate using our colony picking robot or a liquid handling robot.

For more information, please visit our wiki.

Our colony picking robot can not only pick colonies and plate cultures, but it can also use its pins to transfer small amounts of liquid from one plate to another. This can be used to inoculate a fresh plate from a cryo-stock to start your experiment or simply to replicate a previously grown culture. In the same way, four 96-well plates can be inoculated into one 384-well plate (library compression) to create a compact cryo-stock or the other way around (library expansion).

For more information, please visit our wiki.

In our shaking incubator for shallow plates, up to 44 plates can be incubated under temperature (4 °C to 50 °C) and humidity (up to 95%) control. This way, even long term incubations can run with minimal evaporation. Also our deep-well plate shaking incubator is able to control humidity (up to 80%) and temperature (RT to 37 °C) for 8 deep-well plates. Shallow plates can then directly be measured in the plate reader at regular intervals. For deep-well plates, samples can be taken with our liquid handling robots and subsequently measured.

For more information, please visit our wiki.

Similar to the microbial growth and fluorescence monitoring we can monitor the growth of multiple plates and then decide to process the plates based on a condition like time interval or plate reader measuring results. For instance, you can dilute your culture every time it crosses a certain OD threshold and thus extend your plate cultivation over long periods or adjust the medium conditions over time.

For more information, please visit our wiki.

With our liquid handling robots, we offer several methods to produce dilution curves of compounds and testing strains. The plates can also be sealed with foil to prevent evaporation and cross-contamination. Whenever needed in the workflow, the plates can be automatically peeled.

For more information, please visit our wiki.

We have solutions to automate plasmid minipreps in our facility using magnetic beads. One of them is the stand-alone magnetic bead handling robot, KingFisher Apex. To run multiple 64- or 24-well plates and automatically prepare all buffers, we can use our liquid handlers combined with the integrated magnetic bead handling device.

For more information, please visit our wiki.

Similar to our solutions for plasmid miniprep, also protein preps can be done on our stand-alone (link KingFisher Apex) and integrated (link KingFisher Presto) systems to purify proteins. Click here to learn more.

For more information, please visit our wiki.

Almost any pipetting workflow that you can do on your bench manually can – with a few adjustments – be performed by one of our liquid handling robots. Using these robots, your workflow can, for instance, become more reproducible, more accurate, or scaled up to more samples.

For more information, please visit our wiki.

We help our users to transform their bench assay into an automated method. Starting from a robust bench assay we evaluate which of our robots is best suited for the project. Adaptions to the assay or to the robot may be necessary at this point. After the initial programming and logical testing of the automated method, we perform pilot experiments using samples as close to the final assay as possible and fine-tune the hardware to get the best performance. After successful validation we document and hand-over the method to the users for independent use. Methods are continuously evolving around the needs of our users and can be adapted as required.

For more information, please visit our wiki.

A list of our equipment and their capabilities can be found here.

Contact LAF for services, location, and information requests