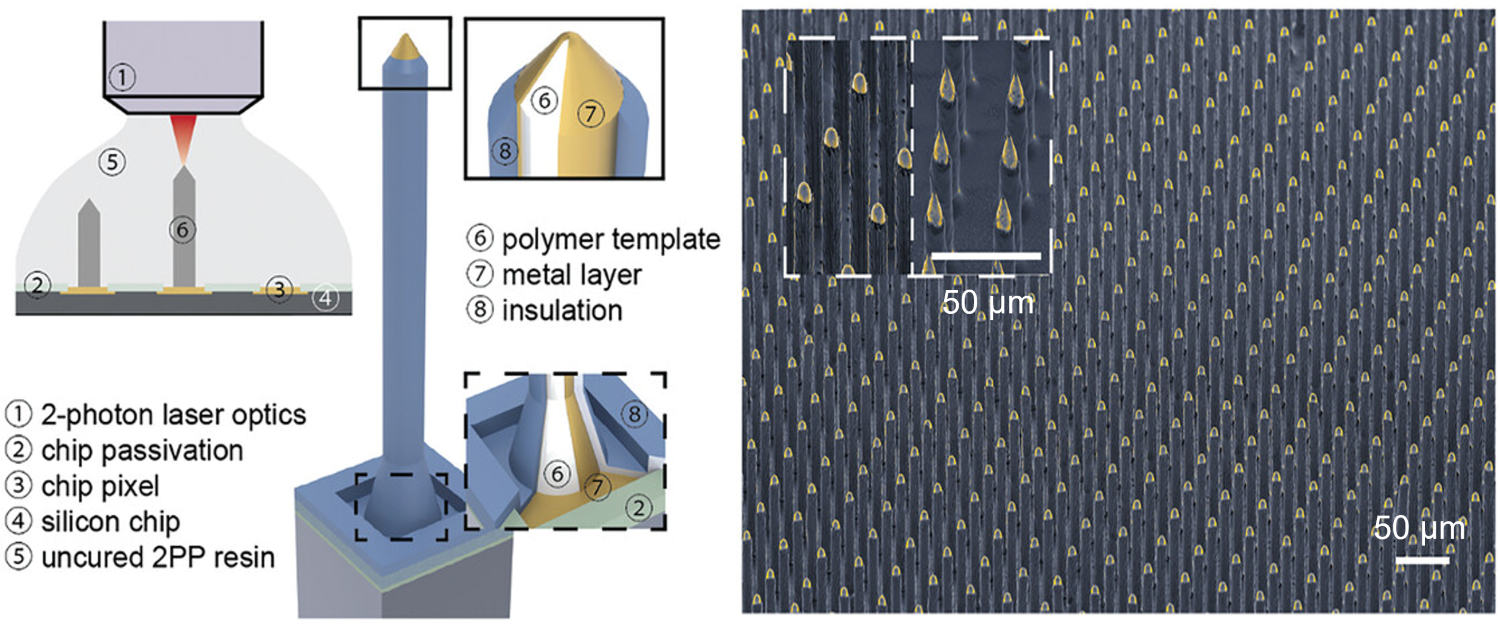

Direct printing of 3D electrodes on CMOS arrays

Method for fabricating tissue-penetrating 3D microelectrodes directly on our planar microelectrode array chips by using high-resolution 3D printing and 2-photon polymerization developed by collaborators in Stanford.

A method for fabricating tissue-penetrating 3D microelectrodes directly onto our planar CMOS-based HD-MEAs using high-resolution 3D printing and 2-photon polymerization and scalable microfabrication technologies was developed by collaborators in Stanford and published in Advanced Science (P. Wang, et al. "Direct-print 3D electrodes for large-scale, high-density, and customizable neural interfaces", Advanced Science 2024, Article 2408602). The presented approach enables to customize electrode shape, height, and positioning for precise targeting of neuron populations in 3D. The effectiveness of this approach was demonstrated by selectively targeting retinal ganglion cell (RGC) somas in the retina while avoiding the axon bundle layer. 6,600-microelectrode, 35-µm-pitch, penetrating electrode arrays were fabricated to obtain high-fidelity, high-resolution, and large-scale retinal recording with little axonal interference. Confocal microscopy further confirmed the precise placement of the microelectrodes. The developed technology can be a versatile tool for interfacing CMOS microelectronics with neural structures at a large scale and cellular resolution.