Bioproduction of value-added compounds

By re-programming the genetic code of cell factories, we can alter components, Such as enzymes and other proteins involved in the chemical and pharmaceutical industries. The alterations can increase the productivity of cells, enhance their stability towards environmental conditions, or exploit novel functionality for the research community.

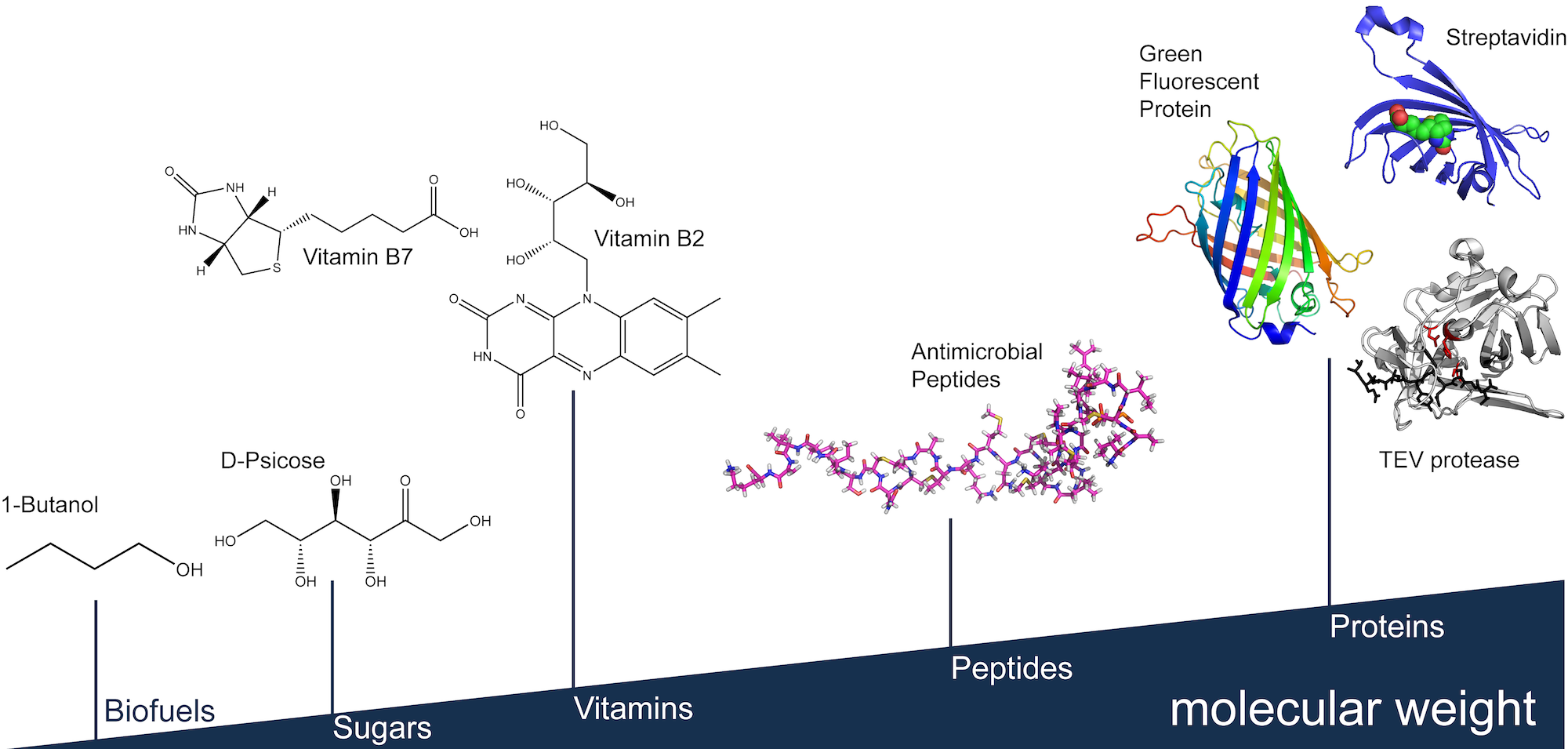

We like to work with real world molecules either already applied or potentially of interest for industrial, pharmaceutical, or research applications. The spectrum of substance classes is broad and includes examples such as high-value added chemical intermediates (fine chemicals), vitamins, biopolymers such as peptides or polynucleotides as well as proteins.

Biofuels

Processes that synthesize biofuels from renewable carbon sources are important for an increasingly decarbonised future. We engineer novel whole-cell biocatalysts using methods from protein, metabolic and genomic engineering and combine them with high-throughput screening technologies. Our current focus is on second generation molecules, i.e. fuels other than fatty acid methyl esters or ethanol.

Enzymes and processes for sugar production

Previously, our research focused on the efficient production of rare sugars. For this we optimized enzymes by means of directed evolution and high-throughput screening and developed optimized intensified production processes using simulated moving bed (SMB) chromatography.

References

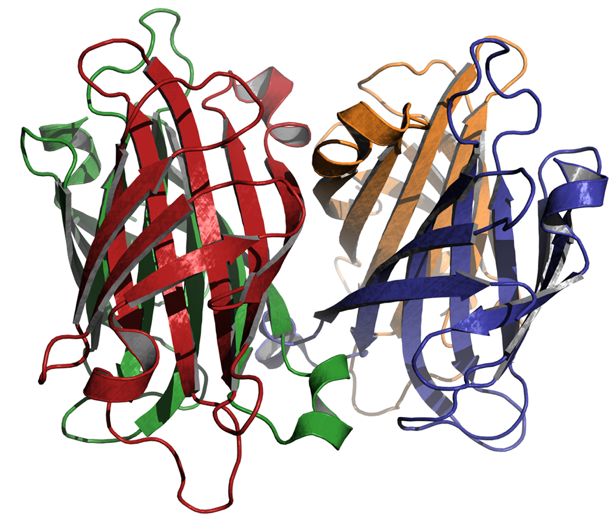

A. Bosshart, S. Panke and Ma. Bechtold: Systematic Optimization of Interface Interactions Increases the Thermostability of a Multimeric Enzyme, Angewandte Chemie, 2013, external page DOI.

A. Bosshart, N. Wagner, L. Lei, S. Panke and M. Bechtold: Highly efficient production of rare sugars D-psicose and L-tagatose by two engineered D-tagatose epimerases, Biotechnology and Bioengineering, 2015, external page DOI.

N. Wagner, A. Bosshart, J. Failmezger, M. Bechtold and S. Panke: A Separation-Integrated Cascade Reaction to Overcome Thermodynamic Limitations in Rare-Sugar Synthesis, Angewandte Chemie, 2015, external page DOI.

N. Wagner, E. Håkansson, S. Wahler, S. Panke and M. Bechtold: Multi-objective optimization for the economic production of D-psicose using simulated moving bed chromatography, Journal of Chromatography A, 2015, external page DOI.

Vitamins

Vitamins are organic substances that if not taken up as part of the diet lead to severe or even life-threatening diseases, and include for example important enzyme cofactors. Therefore, industrial vitamin production is important for various applications from pharmaceutical to food and feed applications. Of the thirteen vitamins currently known, few are produced by biological synthesis. We recently developed methods for the optimization of vitamin B2 (riboflavin)-producing microbes using metabolicand genomic engineering and high-throughput screening. In contrast, for vitamin B7 (biotin) no biosynthetic process is currently available, and we work on novel routes using metabolic engineering, directed evolution and high-throughput screening techniques.

References

A. Meyer, R. Pellaux, S. Potot, K. Becker, H.-P. Hohmann, S. Panke and M. Held: Optimization of a whole-cell biocatalyst by employing genetically encoded product sensors inside nanolitre reactors, Nature Chemistry, 2015, external page DOI.

Peptides

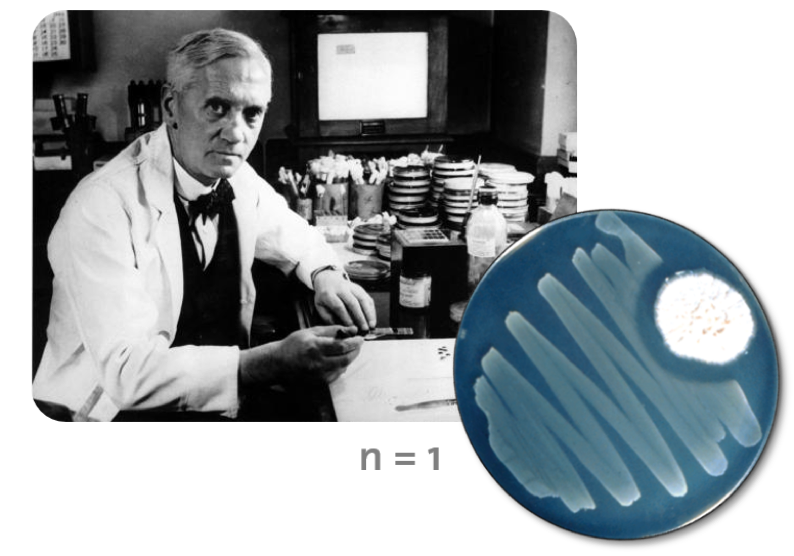

Antimicrobial peptides (AMPs) are synthesized by species from all kingdoms of life as biodefense tools for coping with bio-threats (e.g. tumor cells or pathogens). To date, more than 10,000 AMPs were described, but most of them are still poorly characterized. We evolve and engineer peptides employing high throughputexperimentation and characterization for antimicrobial function using flow cytometric (e.g. the nanoFleming) and next generation sequencing-based approaches. Our current focus is on lantibiotics, Bac7, and other peptides that are amenable to structure variation.

Engineering of hosts for the production of streptavidin

We engineer biotin-independent E. coli and C. glutamicum strains for improved production processes of toxic streptavidin for use in xenobiology applications.

References

M. Jeschek, M.O. Bahls, V. Schneider, P. Marlière, T.R. Ward and S. Panke: Biotin-independent strains of Escherichia coli for enhanced streptavidin production, Metabolic Engineering, 2017, external page DOI.

Engineering of fluorescent proteins

Green fluorescent protein (GFP) is a naturally fluorescent protein with a light-emitting chromophore made of specific amino acid residues. GFP allows for real-time analysis of molecular events in living cells and the use in high-throughput screening approaches. To enable novel applications of this protein we employ genetic engineering of GFP to create variants which, for example, exhibit enhanced stability in acidic environments.

References

T.M. Roberts, F. Rudolf, A. Meyer, R. Pellaux, E. Whitehead, S. Panke and M. Held: Identification and Characterisation of a pH-stable GFP, Scientific Reports, 2016, external page DOI.

Engineering of peptidases/proteases and their production hosts

We engineer the Tobacco Etch Virus (TEV) protease by directed evolution and high-throughput screening towards increased stability and catalytic activity for use in cell-free production of fine chemicals and metabolic engineering.